- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

EnglishViews: 0 Author: Site Editor Publish Time: 2024-01-26 Origin: Site

In the thick film printing process of electronic components, CCD visual alignment system can automatically rectify, can effectively control the error caused by manual feeding, and improve the yield of mass production, which is widely used in high precision thick film printing. However, due to the complexity of the operation and debugging, the technical workers are highly required in the production and use. Recently, there are a lot of old customers buyback, put forward whether to simplify the difficulty of operation, improve the printing accuracy.

In view of these problems, in 2023, we visited a number of customer companies to understand the actual production needs, organized the company's technical team to discuss the positioning system for many times, and arranged technical personnel to communicate with customers for many times. Finally, we, ignoring the cost input, we extensively upgraded the existing software, and introduced a new CCD visual alignment system.

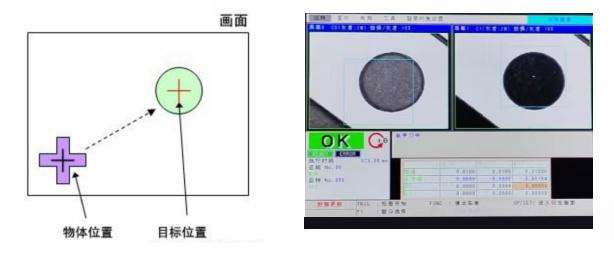

Introduction of traditional alignment mode: manually align the product with the position of the web board, and then align the visual lens at the product to grasp the MARK point. The alignment rate of the product and the mesh board pattern completely depends on the state of the first manual alignment. Then after the deviation is found, the platform compensation (manual input compensation data, automatic compensation when matching). When the product and the mesh graphics meet the production standards, the adjustment is completed.

Introduction to the new version: take out the graphics of the mesh board (MARK point) by printing, CCD sets the MARK point by benchmark, and then place the product to be printed, and log in the MARK point (template) of the product. Partial, the template will automatically move to the benchmark to achieve the product and the mesh graphics completely overlap.

Home / Products / Why OLAT / Manufacturing / Application / Support / News / Contact Us / privacy policy